Statistical Quality Control (S.Q.C.) : Meaning, Purpose, Quality of a product, Chance and Assignable Variation, Process Control and Product Control.

Statistical

Quality Control (S.Q.C.)

Quality:

In consumer's view, quality of a

product means fitness of product for use, while in manufacturer's view, quality

means conformance to specification.

Def":

Quality is one or more

characteristics that a product should possess.

Dimensions of quality:

1. Performance- Will the product do the intended

job?

2. Reliability- How often does the product fail?

3. Durability- How long does the product last?

4. Serviceability- How easy is it to repair the

product?

5. Aesthetics - How does the product look like?

6. Features - What does the product do?

7. Perceived Quality- What is the reputation of the

company or its product?

8. Conformance to standards - Is the product made exactly as the designer intended?

Quality Characteristics:

The factors that jointly describe

the quality of the product are-

i)

Physical - Length,

Weight, Voltage

ii) Sensory - Taste, Appearance, Color

iii) Time oriented - Reliability, Durability, and

Serviceability

S.Q.C.:

Meaning-

By

statistical quality control, we mean the various statistical methods, used for

the maintenance of quality in a manufacturing product. In every manufacturing

process, it is essential that product should possess the quality which the

consumer wants. But in any manufacturing process, it is not possible to produce

products of exactly the same quality. For every process, variation in the

quality of manufactured products is inevitable.

This variation may be due to two

causes: 1) Chance causes

2) Assignable causes

Purpose:

The

main purpose of S.Q.C. is to device the statistical methods, for separating

chance causes from assignable causes; so that we may take appropriate steps as

quickly as possible whenever assignable causes are present in the process Our

aim is to control the manufacturing process so that the proportion of items is

not excessively large.

Chance causes:

In

any manufacturing process & inspection, some stable pattern of variation is

inherent. This pattern of variation is due to many minor causes, which behaves

in random manner. This causes cannot be prevented, therefore this variation is

called allowable. For ex: there may be a slight variation in the electric current

supplied to the machine, there may be slight vibrations of the machines. The

variation in the quality due to such factors is very small & tolerable.

Assignable causes:

The

second type of variation in any production process is due to non random causes

& called as assignable causes. The assignable causes includes the factors

like raw material of bad quality, improper setting of machines, wrong handling

of machines, machine defects, unskilled workers etc. Variations caused by these

factors are generally high & cannot be tolerable. When such causes are

present, quality of the product is lost. Assignable causes can be identified &

eliminated from the process by taking proper care.

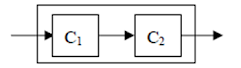

Process control:

In

any manufacturing process, the quality of a product is affected by chance &

assignable causes. If the items produced by the production process indicate the

presence of assignable causes we may search for assignable causes & remove

them from the production process, so that the items produced by the process

will be free from assignable causes & hence of good quality. This is known

as 'process control' & is achieved by the technique of control charts.

Product control (Lot control) :

Product

control is concerned with the inspection of items already produced. After

inspection of items it is decided whether to accept the lot or not. Product

control is mainly achieved by ‘acceptance sampling plans’.

©

Comments

Post a Comment