Statistical Quality Control (SQC) : Control chart; Major parts, Theoritical basis of 3 σ Control Limits, Types of Control chart

Control Charts:

In industry we have to face two kinds of problems.

i) Whether the process confirms to

given standard &

ii) To improve the level of

standard by reducing variability of quality.

Both the problems can be answered

by using Shewhart's control charts.

Major Parts of Control Charts:

i) Quality scale:

It is a vertical scale marked according to the

quality characteristics of each sample.

ii) Sample numbers:

The samples to be plotted on the

control charts are numbered individually & consecutively on the horizontal line, which

is stressed at the bottom of the control chart.

iii) Horizontal lines (Control

lines): There

are three horizontal lines.

a) Central line (C.L.) - This indicates the desired standard or level of the process.

b) Upper Control line (U.C.L.) - This is the line above central line, which is usually 3-σ distance above central line. It indicates the upper limit of tolerance.

c) Lower Control line (L.C.L.) -This is the line below central

line, which is usually 3-σ distance below

central line. It indicates lower limit of tolerance.

d) Plotted samples- Instead of plotting, individual

items of the sample on the control chart, only the quality of entire sample

represented by a single value is plotted.

A point outside the control limits

shows the lack of control situation.

Let T = t(x1, x2,…,xn)

is a function of sample observations and let

E (T) = µt and V (T) = σ2t .

If T is normally distributed, then P (| (T- µt )/σt | ≤ 3) =0.9973 (from normal table).

Thus the probability that t will

fall outside (µt - 3σt,

µt + 3σt)

is 0.0027 which is very small. In other words if variable quality

characteristic is normally distributed and no assignable causes are present in

the process only 27 out of 10000 values of quality characteristics will fall

outside the 3-σ limits. Since 27 out of 10000 is very small and hence

negligible. In the absence of assignable causes, it is expected that all the

values of quality characteristics should lie within 3-σ limits. If at least

one value lies outside the 3-σ![]() limits one suspect

the presence of assignable causes and says that the process is out of control.

limits one suspect

the presence of assignable causes and says that the process is out of control.

If

the statistic does not follow normal distribution, then by Chebyshev's

inequality for any K > 0,

P(|(T- µt ) | ≤ Kσt) ≥ 1 – 1/ K2

By taking K = 3,

P(|(T- µt )/| ≤ 3σt) ≥ 8/9 which is fairly high probability. Thus, even if the quality characteristic does not follow normal distribution, the 3-σ control limits can be used.

Thus, the central line is at µt, that is CL = µt

UCL = µt + 3σt ---- (1)

LCL = µt - 3σt

Type of Control Charts

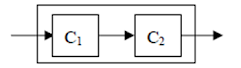

1) Control charts for variables

2) Control charts for attributes

Comments

Post a Comment